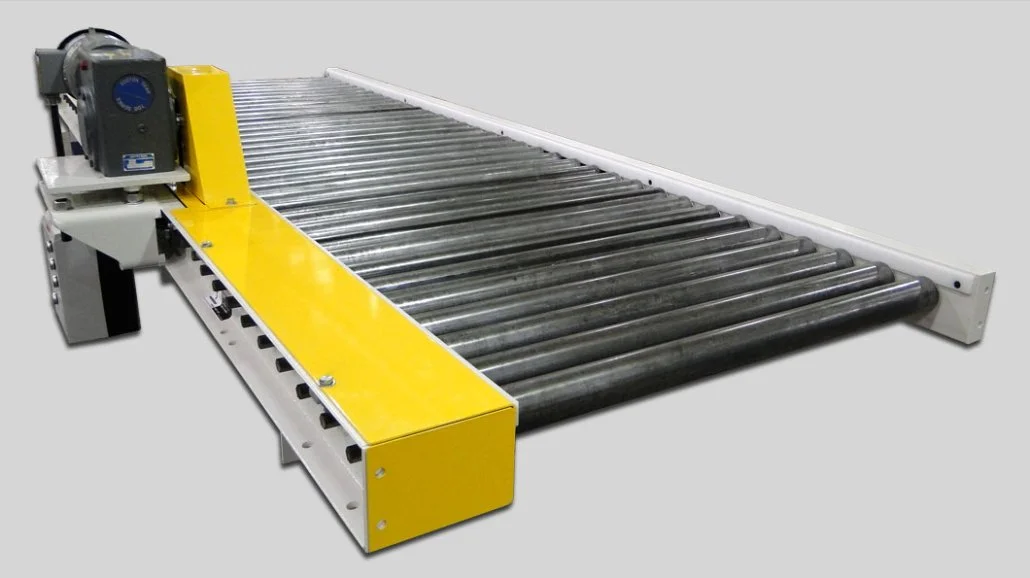

SPR DRIVEN CLDR

SPR DRIVE DESIGN

The SPR (single precision roller) drive is accomplished by utilizing a single roller mounted to the frame with 2-bolt flange, precision bearings. Rotation is delivered via a B-hub sprocket keyed to the roller shaft. The A-plate sprockets welded to the roller tube deliver rotation to the rest of the rollers through a series of roll-to-roll chain loops. The easily removable and interchangeable single sprocket allows for close to 180 degrees of chain wrap in every configuration and an added dimension of speed flexibility. The innovative sliding drive take-up provides a maintenance friendly method of adjusting the drive chain tension.

FEATURES:

One drive roller instead of two

Horizontal sliding chain tensioning

Drive sprocket independent from the roller for easy replacement

Modular design — compatible with all other Omni equipment

Motor placement can be either side of the conveyor frame

Many motor/reducer combinations available